Automotive hydraulic brake parts endurance test system solution

Push rod drive

As a part of the brake system and the clutch system simulation, how to reasonably simulate the actual working state is the key to the push rod drive. The operating frequency, push and return speeds, and push time intervals all require control adjustments to achieve durability testing of test specimens at different displacements and speeds.

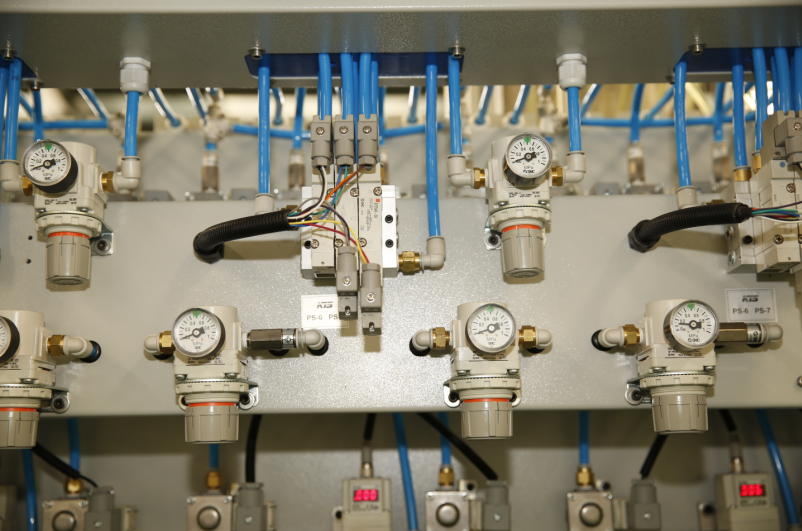

Hydraulic system

In the endurance test bench of automotive hydraulic brake components, the hydraulic system is large and complicated, and the modular design and reasonable layout are the key to the hydraulic system. Aesthetics is only the surface of the hydraulic system. The shortest pipeline and the simplest exhaust method are the essence of the hydraulic system.

Environmental box

We work with leading environmental chamber manufacturers to provide an integrated test environment that can be reliably tested under a wide range of temperatures and humidity. The test bench provides a standard interface for easy integration of the environmental chamber with the test bench system.

Monitoring of physical quantities such as displacement, hydraulic pressure and vacuum

Real-time monitoring of individual systems is critical during the endurance test of hydraulic brake components. The physical quantity monitoring system can collect the physical quantities in the test process in real time, and can judge whether the data is qualified by the control system in real time, so as to judge whether the test process is normal. If the test data exceeds the qualified range, the equipment automatically judges and alarms, if the number of unqualified times exceeds By setting the number of times, the device can automatically stop the test and save the unqualified data.

Main performance

◆Input force: 0~2000N

◆Input displacement: 0~50mm

◆ Vacuum range:

0~-100Kpa

◆ Hydraulic loading range:

0~25Mpa

◆ Working frequency: 500~1200 times/hour can be adjusted

◆ Vacuum test the vacuum inside the pipeline

Stable at -66.7 ± 2.7kPa

◆ Environmental box temperature:

-50°C~+150°C

◆ Environmental test chamber heating rate:

+20°C~+150°C≥3°C/min

◆ Environmental test chamber cooling rate:

+20°C~-50°C≥1°C/min